Rexroth A2FM/107 61WVZB020 Motor

The Rexroth A2FM/107 61WVZB020 Motor is a premium quality machine with high performance and reliability. The dedicated engineering team uses state-of-the art tooling, equipment and techniques to ensure superior performance, long life and trouble-free operation. Our comprehensive proactive testing program includes vibration testing and emission compliance.

Features

- Large variety of available nominal sizes allows exact adjustment to the application

- High power density

- Very high total efficiency

- High starting efficiency

- Working ports SAE flange or thread

- Optional with integrated pressure relief valve

- Optional with mounted additional valve: counterbalance valve (BVD/BVE), flushing and boost-pressure valve

- Bent-axis design

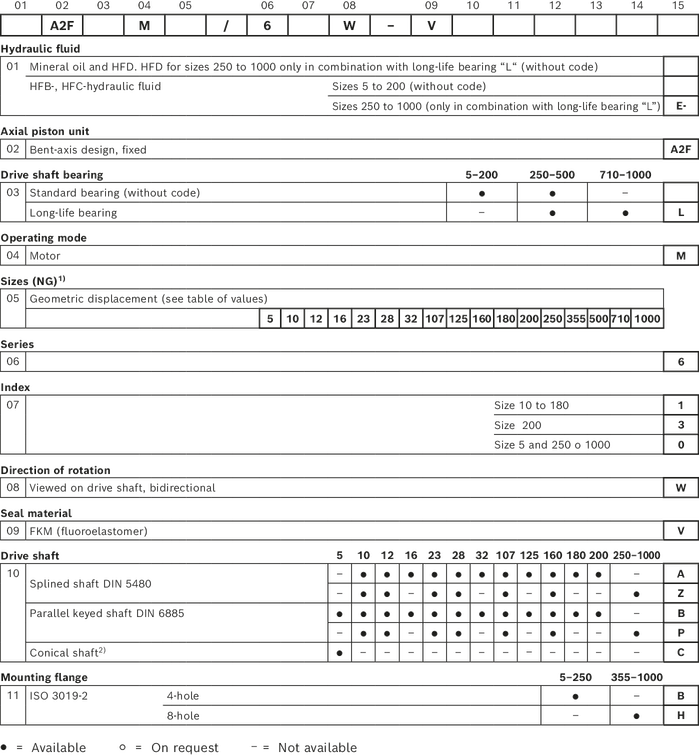

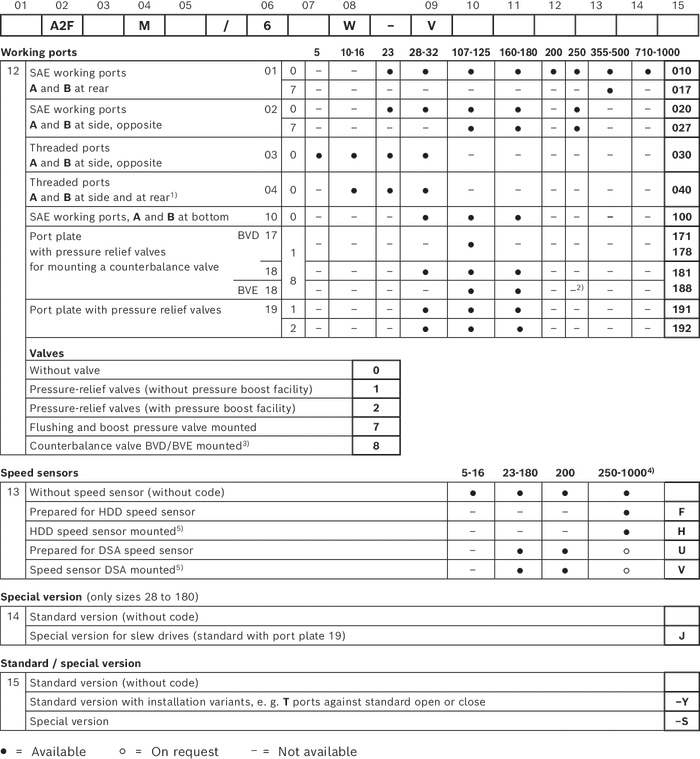

Type code

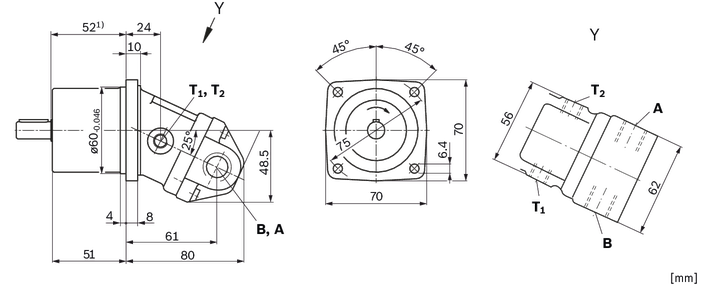

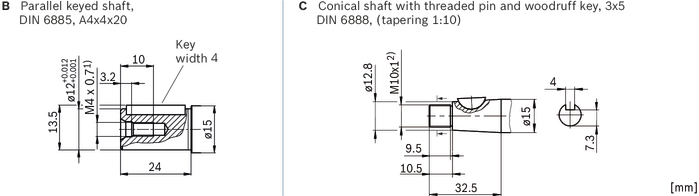

Dimensions

| Working port | Size | M18 × 15; 12 mm deep |

| Standard 1) | DIN 3852 | |

| State on delivery | With protective cover (must be connected) | |

| Drain port | Size | M10 × 1; 8 mm deep |

| Standard 1) | DIN 3852 | |

| State on delivery 2) | Plugged (observe installation instructions) | |

| Drain port | Size | M10 × 1; 8 mm deep |

| Standard 1) | DIN 3852 | |

| State on delivery 2) | Plugged (observe installation instructions) |

Technical data

Table of values

| Displacement geometric, per revolution |

Vg | cm³ | 4.93 | 10.3 | 12 | 16 | 22.9 | 28.1 | 32 | 45.6 | 56.1 | 63 | 80.4 | 90 | 106.7 | 125 | 160.4 | 180 | 200 | 250 | 355 | 500 | 710 | 1000 | |

| Nominal pressure | pnom | bar | 315 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 350 | 350 | 350 | 350 | 350 | |

| Maximum pressure | pmax | bar | 350 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 400 | 400 | 400 | 400 | 400 | |

| Maximum speed 1) | nnom | rpm | 10000 | 8000 | 8000 | 8000 | 6300 | 6300 | 6300 | 5600 | 5000 | 5000 | 4500 | 4500 | 4000 | 4000 | 3600 | 3600 | 2750 | 2700 | 2240 | 2000 | 1600 | 1800 | |

| nmax 2) | rpm | 11000 | 8800 | 8800 | 8800 | 6900 | 6900 | 6900 | 6200 | 5500 | 5500 | 5000 | 5000 | 4400 | 4400 | 4000 | 4000 | 3000 | |||||||

| Inlet flow 3) | at nnom | qV | l/min | 49 | 82 | 96 | 128 | 144 | 177 | 202 | 255 | 281 | 315 | 362 | 405 | 427 | 500 | 577 | 648 | 550 | 675 | 795 | 1000 | 1136 | 1600 |

| Torque 4) | at pnom | M | Nm | 24.7 | 66 | 76 | 102 | 146 | 179 | 204 | 290 | 357 | 401 | 512 | 573 | 679 | 796 | 1021 | 1146 | 1273 | 1393 | 1978 | 2785 | 3955 | 5570 |

| Rotary stiffness | c | kNm/rad | 0.63 | 0.92 | 1.25 | 1.59 | 2.56 | 2.93 | 3.12 | 4.18 | 5.61 | 6.25 | 8.73 | 9.14 | 11.2 | 11.9 | 17.4 | 18.2 | 57.3 | 73.1 | 96.1 | 144 | 270 | 324 | |

| Moment of inertia for rotary group | JTW | kg·m² | 0.00006 | 0.0004 | 0.0004 | 0.0004 | 0.0012 | 0.0012 | 0.0012 | 0.0024 | 0.0042 | 0.0042 | 0.0072 | 0.0072 | 0.0116 | 0.0116 | 0.022 | 0.022 | 0.0353 | 0.061 | 0.102 | 0.178 | 0.55 | 0.55 | |

| Case volume | V | l | 0.17 | 0.17 | 0.17 | 0.2 | 0.2 | 0.2 | 0.33 | 0.45 | 0.45 | 0.55 | 0.55 | 0.8 | 0.8 | 1.1 | 1.1 | 2.7 | 2.5 | 3.5 | 4.2 | 8 | 8 | ||

| Weight (approx.) | m | kg | 2.5 | 5.4 | 5.4 | 5.4 | 9.5 | 9.5 | 9.5 | 13.5 | 18 | 18 | 23 | 23 | 32 | 32 | 45 | 45 | 66 | 73 | 110 | 155 | 325 | 336 | |

1) These values are valid at:

– for the optimum viscosity range from vopt = 36 to 16 mm2/s

– with hydraulic fluid based on mineral oils

2) Intermittent maximum speed: overspeed for unload and overhauling processes, t < 5 s and Δp < 150 bar

3) Restriction of input flow with counterbalance valve

4) Torque without radial force, with radial force see table “Permissible radial and axial forces of the drive shafts”

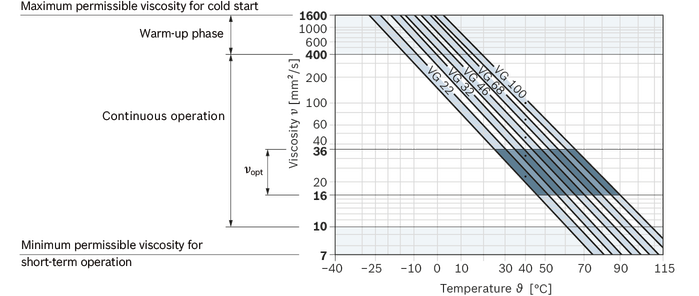

Viscosity and temperature of hydraulic fluids

| Cold start | νmax ≤ 1600 mm²/s | NBR2) | ϑSt ≥ -40 °C | t ≤ 3 min, without load (p ≤ 50 bar), n ≤ 1000 rpm (size 5 to 200), n ≤ 0.25 • nnom (size 250 to 1000), permissible temperature difference between axial piston unit and hydraulic fluid max. 25 K |

| FKM | ϑSt ≥ -25 °C | |||

| Warm-up phase | ν = 400 … 1600 mm²/s | t ≤ 15 min, p ≤ 0.7 • pnom and n ≤ 0.5 • nnom | ||

| Continuous operation | ν = 10 … 400 mm²/s3) | NBR2) | ϑ ≤ +78 °C | measured at port T |

| FKM | ϑ ≤ +103 °C | |||

| νopt = 16 … 36 mm²/s | range of optimum operating viscosity and efficiency | |||

| Short-term operation | νmin = 7 … 10 mm²/s | NBR2) | ϑ ≤ +78 °C | t ≤ 3 min, p ≤ 0.3 • pnommeasured at port T |

| FKM | ϑ ≤ +103 °C |

1) If the specified temperatures cannot be maintained due to extreme operating parameters, please contact us.

2) Special version, please contact us.

3) Equates e.g. with the VG 46 a temperature range of +5 °C to +85 °C (see selection diagram)

Selection diagram

Operating pressure range

| Nominal pressure | pnom | see table of values | The nominal pressure corresponds to the maximum design pressure. |

| Maximum pressure | pmax | see table of values | The maximum pressure corresponds to the maximum operating pressure within the single operating period. The sum of the single operating periods must not exceed the total operating period. |

| Single operating period | 10 s | ||

| Total operating period | 300 h | ||

| Minimum pressure | pHP min | 25 bar | Minimum pressure on high-pressure side (port A or B) required to prevent damage to the axial piston unit. |

| Minimum pressure at inlet (pump operating mode) | pE min | see diagram | To prevent damage to the axial piston motor in pump mode (change of high-pressure side with unchanged direction of rotation, e.g. when braking),a minimum pressure must be guaranteed at the working port (inlet). The minimum pressure depends on the rotational speed and displacement of the axial piston unit. |

| Total pressure | pSu | 700 bar | The summation pressure is the sum of the pressures at both work ports (A and B). |

| with integrated pressure relief valve | RA max | 9000 bar/s | Maximum permissible rate of pressure build-up and reduction during a pressure change over the entire pressure range. |

| without pressure relief valve | RA max | 16000 bar/s | |

| Continuous differential pressure | ΔpT cont | 2 bar | Maximum averaged differential pressure at the shaft seal (case to ambient pressure) |

| Pressure peaks | pT peak | 10 bar | t < 0.1 s |

Rexroth A2FM/107 61WVZB020 Motor Service Manual

The Rexroth A2FM/107 61WVZB020 Motor is an air motor with an output torque of 250 Nm and output volume of 160 Nm. The motor fulfills the requirements of industrial standard machine tools and therefore is suitable for positioning and holding as well as clamping machines in shaping, clamping and sheet metal trimming machines or in workshop automation systems. One can find the complete selection on our website under the keyword Motor.

Click to download the manual for free