Rexroth A2FE107/61W-VZL181 Hydraulic Pump

Rexroth A2FE107/61W-VZL181 Hydraulic Pump are essential for providing fluid power in most industrial applications. They are also used in a wide range of other machines and devices, such as agricultural tractors, irrigation systems and even cars. To ensure the long-term reliability of these products, Rexroth offers an extensive range of hydraulic pump spares that include replacement and repair parts.

Features

- 3 pressure ranges to fit to different customer requirements and applications

- Space-saving construction due to recessed mounting flange

- Very high power density

- Very high total efficiency

- High starting efficiency

- Optional with integrated flushing valve

- Robust 40° bent-axis technology

- Bent-axis design

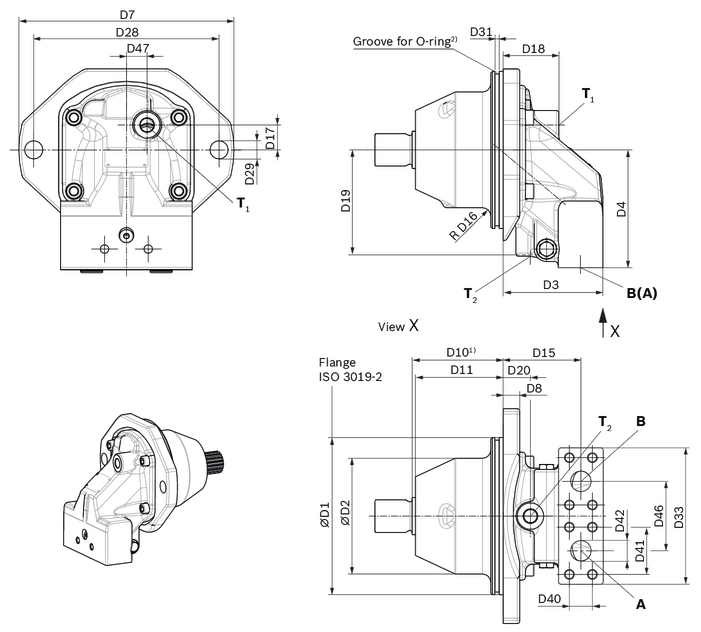

Dimensions

SAE working ports at bottom

Dimensions

1)To shaft collar

2)The O-ring is not included in the delivery contents.

| Version | Size | D1 | D2 | D3 | D4 | D7 | D8 | D9 | D10 | D11 | D12 | D13 | D14 | D15 | D16 | D17 | D18 | D19 | D20 | D25 | D26 | D28 | D29 | D31 | D33 | D40 | D41 | D42 | D46 | D47 | O-ring |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | ||

| A2FEN | 28 | 125 | 172.7 | 122 | 160 | 20 | 10 | 32 | 30 | 86 | 148.7 | 125 | 148.7 | 30 | 126.2 | 121.5 | 93.2 | 150 | 145 | 13.5 | 147 | 23.8 | 50.8 | 19 | 75 | 25 | |||||

| 32 | 125 | 172.7 | 122 | 160 | 20 | 10 | 32 | 30 | 86 | 148.7 | 125 | 148.7 | 30 | 126.2 | 121.5 | 93.2 | 150 | 145 | 13.5 | 147 | 23.8 | 50.8 | 19 | 75 | 25 | ||||||

| 37 | 125 | 172.7 | 122 | 160 | 20 | 10 | 32 | 30 | 86 | 148.7 | 125 | 148.7 | 30 | 126.2 | 121.5 | 93.2 | 150 | 145 | 13.5 | 147 | 23.8 | 50.8 | 19 | 75 | 25 | ||||||

| 45 | 100 | 157 | 100 | 15 | 8 | 25 | 23 | 59 | 130 | 125 | 148.7 | 30 | 126.2 | 121.5 | 93.2 | 150 | 145 | 13.5 | 147 | 23.8 | 50.8 | 19 | 75 | 25 | |||||||

| 56 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 63 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 80 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 90 | 190 | 140.3 | 120.5 | 142 | 260 | 20 | 110 | 106 | 101.5 | 145 | 93.5 | 10 | 30 | 67.5 | 127 | 33 | 224 | 22 | 5.2 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | Ø182 × 4 | |||||

| 107 | 190 | 140.3 | 120.5 | 142 | 260 | 20 | 110 | 106 | 101.5 | 145 | 93.5 | 10 | 30 | 67.5 | 127 | 33 | 224 | 22 | 5.2 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | Ø182 × 4 | |||||

| A2FEM | 23 | 125 | 172.7 | 122 | 160 | 20 | 10 | 32 | 30 | 86 | 148.7 | 125 | 148.7 | 30 | 126.2 | 121.5 | 93.2 | 150 | 145 | 13.5 | 147 | 23.8 | 50.8 | 19 | 75 | 25 | |||||

| 28 | 125 | 172.7 | 122 | 160 | 20 | 10 | 32 | 30 | 86 | 148.7 | 125 | 148.7 | 30 | 126.2 | 121.5 | 93.2 | 150 | 145 | 13.5 | 147 | 23.8 | 50.8 | 19 | 75 | 25 | ||||||

| 32 | 125 | 172.7 | 122 | 160 | 20 | 10 | 32 | 30 | 86 | 148.7 | 125 | 148.7 | 30 | 126.2 | 121.5 | 93.2 | 150 | 145 | 13.5 | 147 | 23.8 | 50.8 | 19 | 75 | 25 | ||||||

| 45 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 56 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 63 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 80 | 190 | 140.3 | 120.5 | 142 | 260 | 20 | 110 | 106 | 101.5 | 145 | 93.5 | 10 | 30 | 67.5 | 127 | 33 | 224 | 22 | 5.2 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | Ø182 × 4 | |||||

| 90 | 190 | 140.3 | 120.5 | 142 | 260 | 20 | 110 | 106 | 101.5 | 145 | 93.5 | 10 | 30 | 67.5 | 127 | 33 | 224 | 22 | 5.2 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | Ø182 × 4 | |||||

| 107 | 140 | 198.5 | 142 | 180 | 20 | 10 | 32 | 29 | 101.5 | 171.5 | 145 | 171.5 | 30 | 145.5 | 127 | 111 | 165 | 160 | 13.5 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | ||||||

| 125 | 140 | 198.5 | 142 | 180 | 20 | 10 | 32 | 29 | 101.5 | 171.5 | 145 | 171.5 | 30 | 145.5 | 127 | 111 | 165 | 160 | 13.5 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | ||||||

| 160 | 200 | 160 | 175 | 157 | 286 | 20 | 122.8 | 119 | 120 | 150 | 126.7 | 88.2 | 131.5 | 47.2 | 250 | 22 | 5.2 | 194 | 31.8 | 66.7 | 32 | 99 | 30 | ||||||||

| 180 | 200 | 160 | 175 | 157 | 286 | 20 | 122.8 | 119 | 120 | 150 | 126.7 | 88.2 | 131.5 | 47.2 | 250 | 22 | 5.2 | 194 | 31.8 | 66.7 | 32 | 99 | 30 | ||||||||

| A2FEH | 45 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | ||||

| 56 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 63 | 160 | 118 | 112.4 | 122 | 235 | 18 | 92.3 | 90 | 86 | 125 | 88.4 | 10 | 30 | 65.9 | 121.5 | 32.9 | 200 | 18 | 5.2 | 147 | 23.8 | 50.8 | 19 | 75 | 20 | Ø150 × 4 | |||||

| 80 | 190 | 140.3 | 120.5 | 142 | 260 | 20 | 110 | 106 | 101.5 | 145 | 93.5 | 10 | 30 | 67.5 | 127 | 33 | 224 | 22 | 5.2 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | Ø182 × 4 | |||||

| 90 | 190 | 140.3 | 120.5 | 142 | 260 | 20 | 110 | 106 | 101.5 | 145 | 93.5 | 10 | 30 | 67.5 | 127 | 33 | 224 | 22 | 5.2 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | Ø182 × 4 | |||||

| 107 | 140 | 198.5 | 142 | 180 | 20 | 10 | 32 | 29 | 101.5 | 171.5 | 145 | 171.5 | 30 | 145.5 | 127 | 111 | 165 | 160 | 13.5 | 165 | 27.8 | 57.2 | 25 | 84 | 25 | ||||||

| 125 | 140 | 198.5 | 142 | 180 | 20 | 10 | 32 | 29 | 101.5 | 171.5 | 145 | 171.5 | 30 | 145.5 | 127 | 111 | 165 | 160 | 13.5 | 165 | 27.8 | 57.2 | 25 | 84 | 25 |

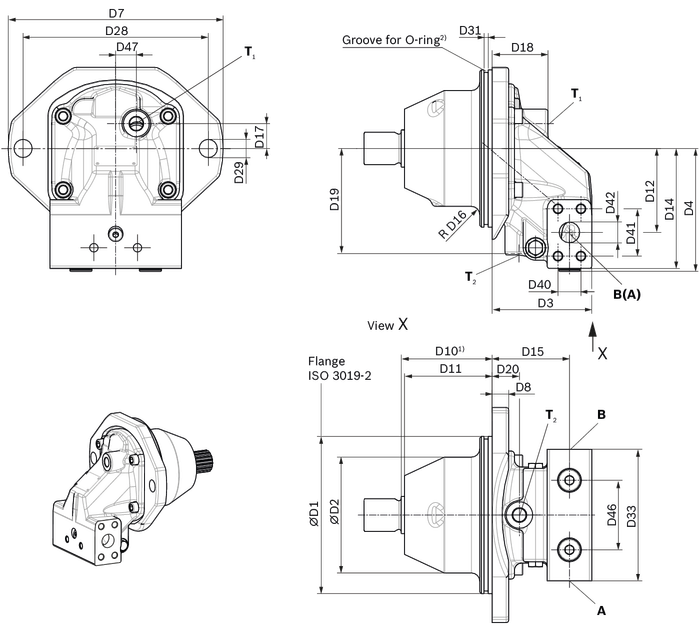

Dimensions

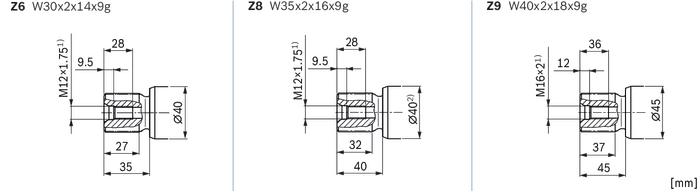

Overview of available drive shafts

A2FEN

| Size | 56 | 63 | 80 | 90 | 107 | |||

| Drive shafts | Code | Z6 | Z8 | Z8 | Z8 | Z9 | Z9 | |

A2FEM

| Size | 45 | 56 | 63 | 80 | 90 | ||||

| Drive shafts | Code | Z6 | Z6 | Z8 | Z8 | Z8 | Z9 | Z9 | |

A2FEH

| Size | 45 | 56 | 63 | 80 | 90 | |||

| Drive shafts | Code | Z6 | Z8 | Z8 | Z8 | Z9 | Z9 | |

Dimensions

Technical data

| Size | 28 | 32 | 37 | 45 | 56 | 63 | 80 | 90 | 107 | 23 | 28 | 32 | 45 | 56 | 63 | 80 | 90 | 107 | 125 | 160 | 180 | 45 | 56 | 63 | 80 | 90 | 107 | 125 | |||

| Version | A2FEN | A2FEM | A2FEH | ||||||||||||||||||||||||||||

| Displacement geometric, per revolution |

Vg | cm³ | 28.1 | 32 | 36.8 | 44.2 | 56.6 | 63 | 81.7 | 90.5 | 108.8 | 22.9 | 28.1 | 32 | 44.9 | 56.6 | 63 | 79.8 | 90.5 | 106.7 | 125 | 160.4 | 180 | 44.9 | 56.6 | 63 | 79.8 | 90.5 | 106.7 | 125 | |

| Nominal pressure | pnom | bar | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | |

| Maximum pressure | pmax | bar | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Maximum speed | nnom 1) | rpm | 4725 | 4725 | 4200 | 4200 | 3750 | 3750 | 3375 | 3375 | 3000 | 6300 | 6300 | 6300 | 5000 | 5000 | 5000 | 4500 | 4500 | 4000 | 4000 | 3600 | 3600 | 5000 | 5000 | 5000 | 4500 | 4500 | 4000 | 4000 | |

| nmax 2) | rpm | 5175 | 5175 | 4650 | 4650 | 4125 | 4125 | 3700 | 3700 | 3300 | 6900 | 6900 | 6900 | 5500 | 5500 | 5500 | 5000 | 5000 | 4400 | 4400 | 4000 | 4000 | 5500 | 5500 | 5500 | 5000 | 5000 | 4400 | 4400 | ||

| Inlet flow | at nnom | qV | l/min | 133 | 151 | 155 | 186 | 212 | 236 | 276 | 305 | 326 | 144 | 177 | 202 | 225 | 283 | 315 | 359 | 407 | 427 | 500 | 577 | 648 | 225 | 283 | 315 | 359 | 407 | 427 | 500 |

| Torque 3) | at pnom | M | Nm | 134 | 153 | 176 | 211 | 270 | 301 | 390 | 432 | 519 | 146 | 179 | 204 | 286 | 360 | 401 | 508 | 576 | 679 | 796 | 1021 | 1146 | 322 | 405 | 451 | 571 | 648 | 764 | 895 |

| Rotary stiffness | c | kNm/rad | 2.2 | 2.46 | 4.29 | 4.84 | 6.97 | 8.11 | 8.47 | 9.85 | 10.96 | 1.76 | 2.2 | 2.46 | 4.65 | 6.97 | 8.11 | 9.1 | 9.85 | 12.49 | 13.65 | 21.32 | 23.04 | 4.65 | 6.97 | 8.11 | 9.1 | 9.85 | 12.49 | 13.65 | |

| Moment of inertia for rotary group | JTW | kg·m² | 0.001 | 0.0011 | 0.0012 | 0.0012 | 0.0034 | 0.0035 | 0.0037 | 0.0058 | 0.0061 | 0.001 | 0.001 | 0.0011 | 0.0033 | 0.0034 | 0.0035 | 0.0056 | 0.0058 | 0.0088 | 0.0091 | 0.0248 | 0.0254 | 0.0033 | 0.0034 | 0.0035 | 0.0056 | 0.0058 | 0.0088 | 0.0091 | |

| Case volume | V | l | 0.3 | 0.3 | 0.3 | 0.3 | 0.6 | 0.6 | 0.6 | 0.65 | 0.65 | 0.3 | 0.3 | 0.3 | 0.6 | 0.6 | 0.6 | 0.65 | 0.65 | 1.1 | 1.1 | 0.8 | 0.8 | 0.6 | 0.6 | 0.6 | 0.65 | 0.65 | 1.1 | 1.1 | |

| Weight (approx.) | m | kg | 10.7 | 10.7 | 10.7 | 10.7 | 17 | 17 | 17 | 23 | 23 | 10.7 | 10.7 | 10.7 | 17 | 17 | 17 | 23 | 23 | 32.8 | 32.8 | 41 | 41 | 17 | 17 | 17 | 23 | 23 | 32.8 | 32.8 | |

| 1) | These values are valid at: – for the optimum viscosity range from vopt = 36 to 16 mm2/s – with hydraulic fluid based on mineral oils |

| 2) | Intermittent maximum speed: overspeed for unload and overhauling processes, t < 5 s and Δp < 150 bar |

| 3) | Torque without radial force, with radial force see table “Permissible radial and axial forces of the drive shafts” |

Note

- The values in the table are theoretical values, without consideration of efficiencies and tolerances. The values are rounded.

- Exceeding the maximum or falling below the minimum permissible values can lead to a loss of function, a reduction in operational service life or total destruction of the axial piston unit. Other permissible limit values, such as speed variation, reduced angular acceleration as a function of the frequency and the permissible angular acceleration at start (lower than the maximum angular acceleration) can be found in data sheet 90261.

Hydraulic fluids

The axial piston unit is designed for operation with mineral oil HLP according to DIN 51524. Application instructions and requirements for hydraulic fluids should be taken from the following data sheets before the start of project planning:

- 90220: Hydraulic fluids based on mineral oils and related hydrocarbons

- 90221: Environmentally acceptable hydraulic fluids

For operation with HF fluids please consult us.

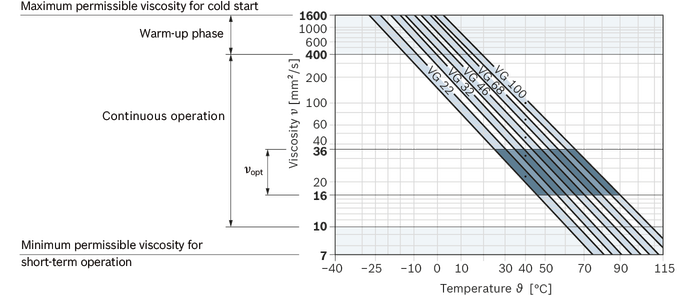

Viscosity and temperature of hydraulic fluids

| Viscosity | Shaft seal |

Temperature1) | Comment | |

| Cold start | νmax ≤ 1600 mm²/s | NBR2) | ϑSt ≥ -40 °C | t ≤ 3 min, without load (p ≤ 50 bar), n ≤ 1000 rpm, permissible temperature difference between axial piston unit and hydraulic fluid max. 25 K |

| FKM | ϑSt ≥ -25 °C | |||

| Warm-up phase | ν = 400 … 1600 mm²/s | t ≤ 15 min, p ≤ 0.7 • pnom and n ≤ 0.5 • nnom | ||

| Continuous operation | ν = 10 … 400 mm²/s3) | NBR2) | ϑ ≤ +78 °C | measured at port T |

| FKM | ϑ ≤ +103 °C | |||

| νopt = 16 … 36 mm²/s | range of optimum operating viscosity and efficiency | |||

| Short-term operation | νmin = 7 … 10 mm²/s | NBR2) | ϑ ≤ +78 °C | t ≤ 3 min, p ≤ 0.3 • pnom

measured at port T |

| 1) | If the specified temperatures cannot be maintained due to extreme operating parameters, please contact us. |

| 2) | Special version, please contact us. |

| 3) | Equates e.g. with the VG 46 a temperature range of +5 °C to +85 °C (see selection diagram) |

Note

To reduce high temperature of the hydraulic fluid in the axial piston unit we recommend the use of a flushing and boost pressure valve (see chapter Extended functions and versions).

Selection of hydraulic fluid

Bosch Rexroth evaluates hydraulic fluids on the basis of the Fluid Rating according to the technical data sheet 90235.

Hydraulic fluids with positive evaluation in the Fluid Rating are provided in the following technical data sheet:

- 90245: Bosch Rexroth Fluid Rating List for Rexroth hydraulic components (pumps and motors)

The hydraulic fluid should be selected so that the operating viscosity in the operating temperature range is within the optimum range (νopt; see selection diagram).

Filtration of the hydraulic fluid

Finer filtration improves the cleanliness level of the hydraulic fluid, which increases the service life of the axial piston unit.

A cleanliness level of at least 20/18/15 is to be maintained according to ISO 4406.

At a hydraulic fluid viscosity of less than 10 mm²/s (e.g. due to high temperatures in short-term operation) at the drain port, a cleanliness level of at least 19/17/14 according to ISO 4406 is required.

For example, the viscosity is 10 mm²/s at:

- HLP 32 a temperature of 73°C

- HLP 46 a temperature of 85°C

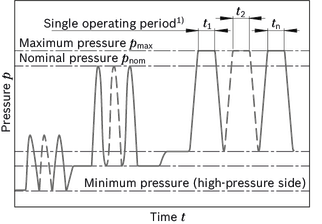

Operating pressure range

| Pressure at working port A or B (high-pressure side) | Definition | ||

| Nominal pressure | pnom | see table of values | The nominal pressure corresponds to the maximum design pressure. |

| Maximum pressure | pmax | see table of values | The maximum pressure corresponds to the maximum operating pressure within the single operating period. The sum of the single operating periods must not exceed the total operating period. |

| Single operating period | 10 s | ||

| Total operating period | 300 h | ||

| Minimum pressure | pHP min | 25 bar | Minimum pressure on high-pressure side (port A or B) required to prevent damage to the axial piston unit. |

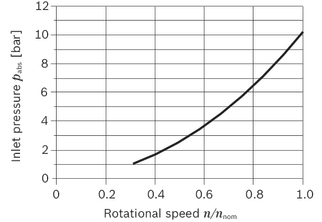

| Minimum pressure at inlet (pump operating mode) | pE min | see diagram | To prevent damage to the axial piston motor in pump mode (change of high-pressure side with unchanged direction of rotation, e.g. when braking),a minimum pressure must be guaranteed at the working port (inlet). The minimum pressure depends on the rotational speed and displacement of the axial piston unit. |

| Total pressure | pSu | 700 bar | The summation pressure is the sum of the pressures at both work ports (A and B). |

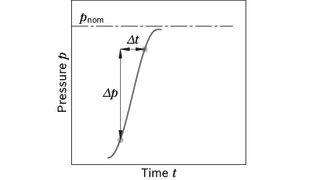

| Rate of pressure change | Definition | ||

| with integrated pressure relief valve | RA max | 9000 bar/s | Maximum permissible rate of pressure build-up and reduction during a pressure change over the entire pressure range. |

| without pressure relief valve | RA max | 16000 bar/s | |

| Case pressure at port T | Definition | ||

| Continuous differential pressure | ΔpT cont | 2 bar | Maximum averaged differential pressure at the shaft seal (case to ambient pressure) |

| Pressure peaks | pT peak | 10 bar | t < 0.1 s |

Note

- Working pressure range valid when using hydraulic fluids based on mineral oils. Values for other hydraulic fluids, please contact us.

Minimum pressure at inlet (pump operating mode)

This diagram is only valid for the optimum viscosity range of vopt = 16 to 36 mm2/s.

If the above mentioned conditions cannot be ensured, please contact us.

Pressure definition

| 1) | Total operating period = t1 + t2 + … + tn |

Rate of pressure change

Note

- The service life of the shaft seal is influenced by the speed of the axial piston unit and the case pressure.

- The service life decreases with an increase of the mean differential pressure between the case and the ambient pressure and with a higher frequency of pressure spikes.

- The case pressure must be equal to or higher than the ambient pressure.

Rexroth A2FE107/61W-VZL181 Hydraulic Pump service mar

Rexroth A2FE107/61W-VZL181 Hydraulic Pump is designed for industrial use and comes with a service manual. The pump is not equipped with an operating instruction book, so you’ll need to refer to the service manual if you have any questions.

Click to download the manual for free